|

|

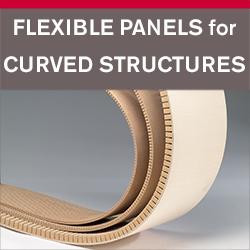

Fabrication Techniques

Framing Technique

- Skin Method

Description Description

Single skin of Neatflex attached to

a framework.

Example Applications

Used in applications where strength,

but light-weight is an advantage, such as reception desks

exhibition cabinets, columns, displays, wavy walls, shop fixtures,

stage and film sets.

Features

& Benefits

• Fast fabrication

• Fast finishing

• Heavy duty applications

| Directions |

1. Fabricate a framework with sufficient shaped

and supporting ribs to support the Neaflex skin.

For example Ð curved ribs would typically be

set at 350 mm to 450 mm centres. |

|

2. Straight ribs used to support the curved ribs

should be set-back from the face of the curved

ribs to ensure they do not interfere with the

Neatflex.

3. Cut

the Neatflex to rough shape and offer up to the

framework to ensure a good fit. Position the Neatflex

grooved face inwards.

|

|

4. Apply a good coat of wood glue to mating surfaces

on the framework and Neatflex, and finally position.

|

|

5. Staple into position with sufficient staples to

retain the shape until the adhesive holds.

6. Trim to shape and finish in the normal way. |

|

|

|